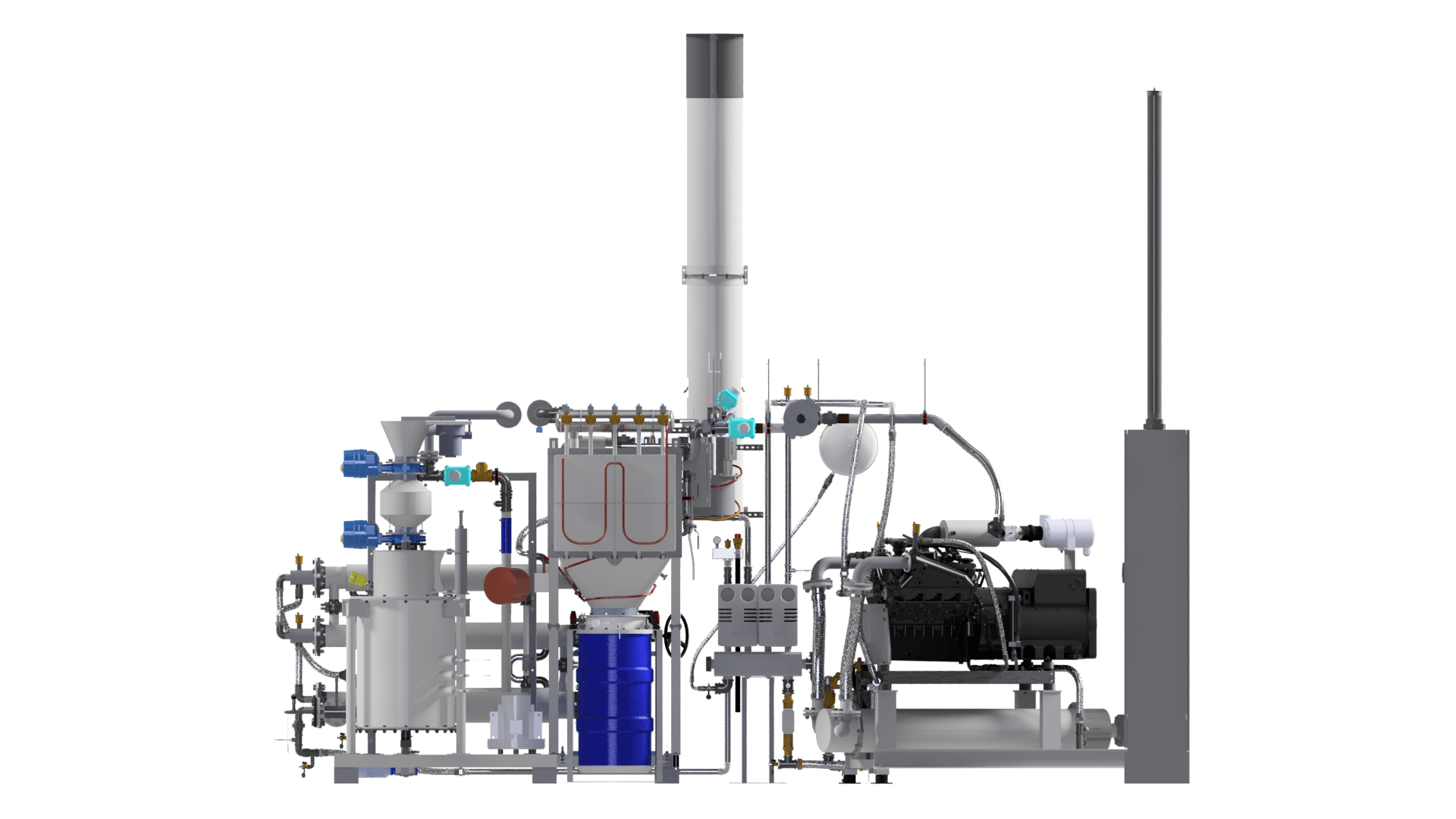

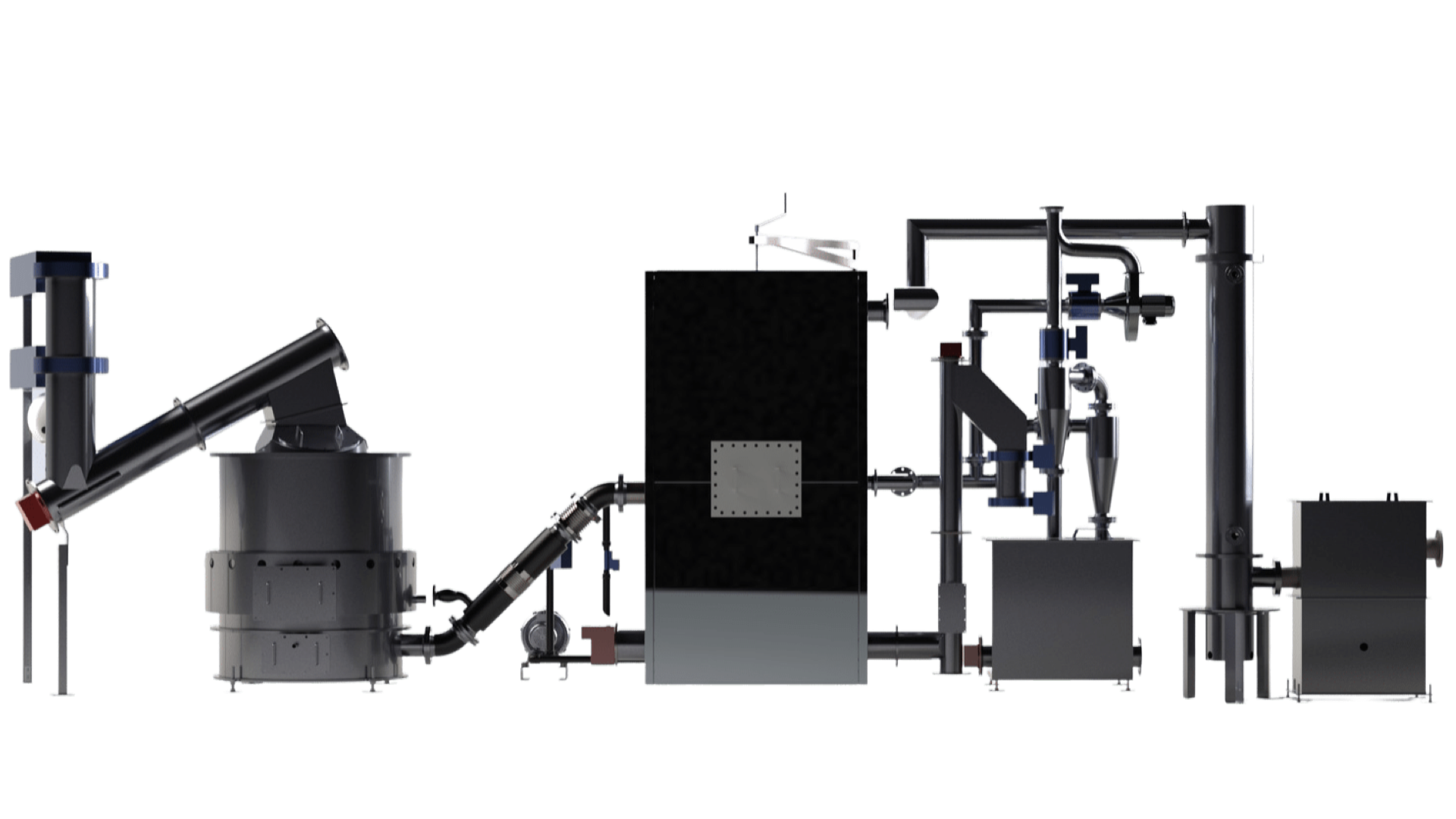

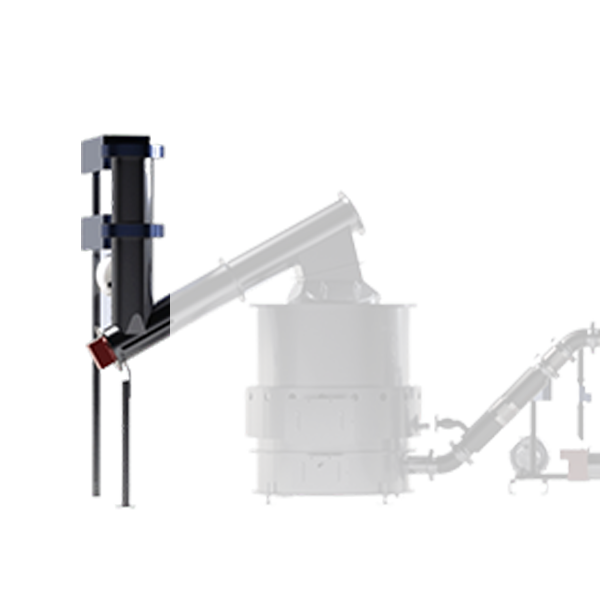

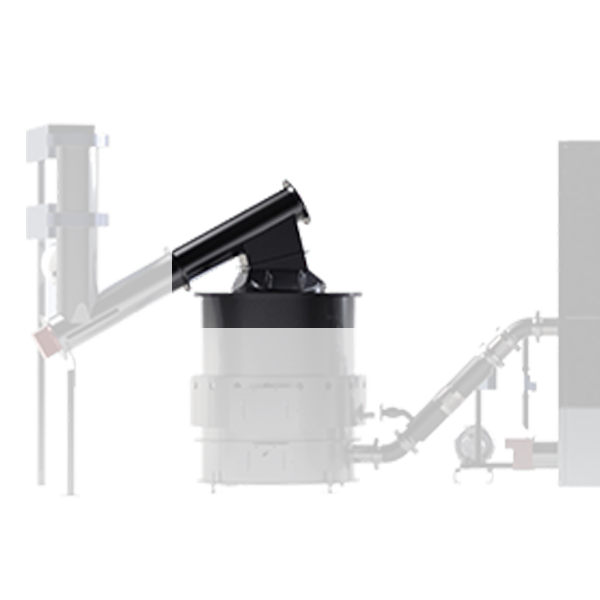

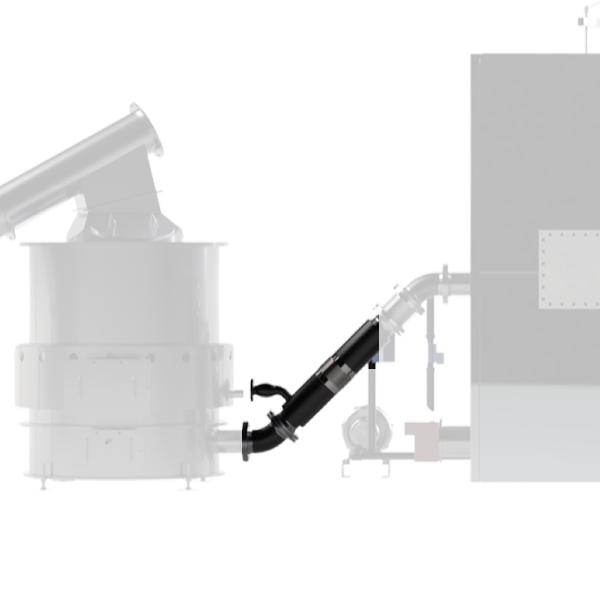

In over 15 years we have developed our products and components to perfection. Developed and tested in-house, we guarantee the longevity of our components. All key components — including engine and generator — are carefully selected and, where necessary, customized to ensure maximum reliability. Moreover, we fulfill the Made in Germany claim by developing and manufacturing our products in Germany.