Mühlbach / South Tyrol

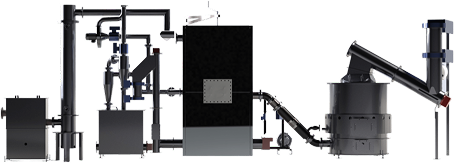

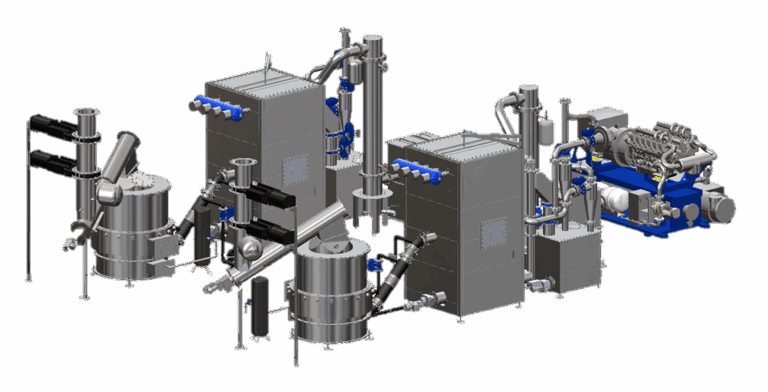

Our wood gas plant for a glulam manufacturer in Mühlbach/South Tyrol went into service in October 2013. The special feature: The plant is not fired with wood chips but with wood briquettes. This required extensive research and testing in advance. Our wood gas plant runs in continuous operation day after day, year after year. It is reliable, low-maintenance and an indispensable part of our production process.