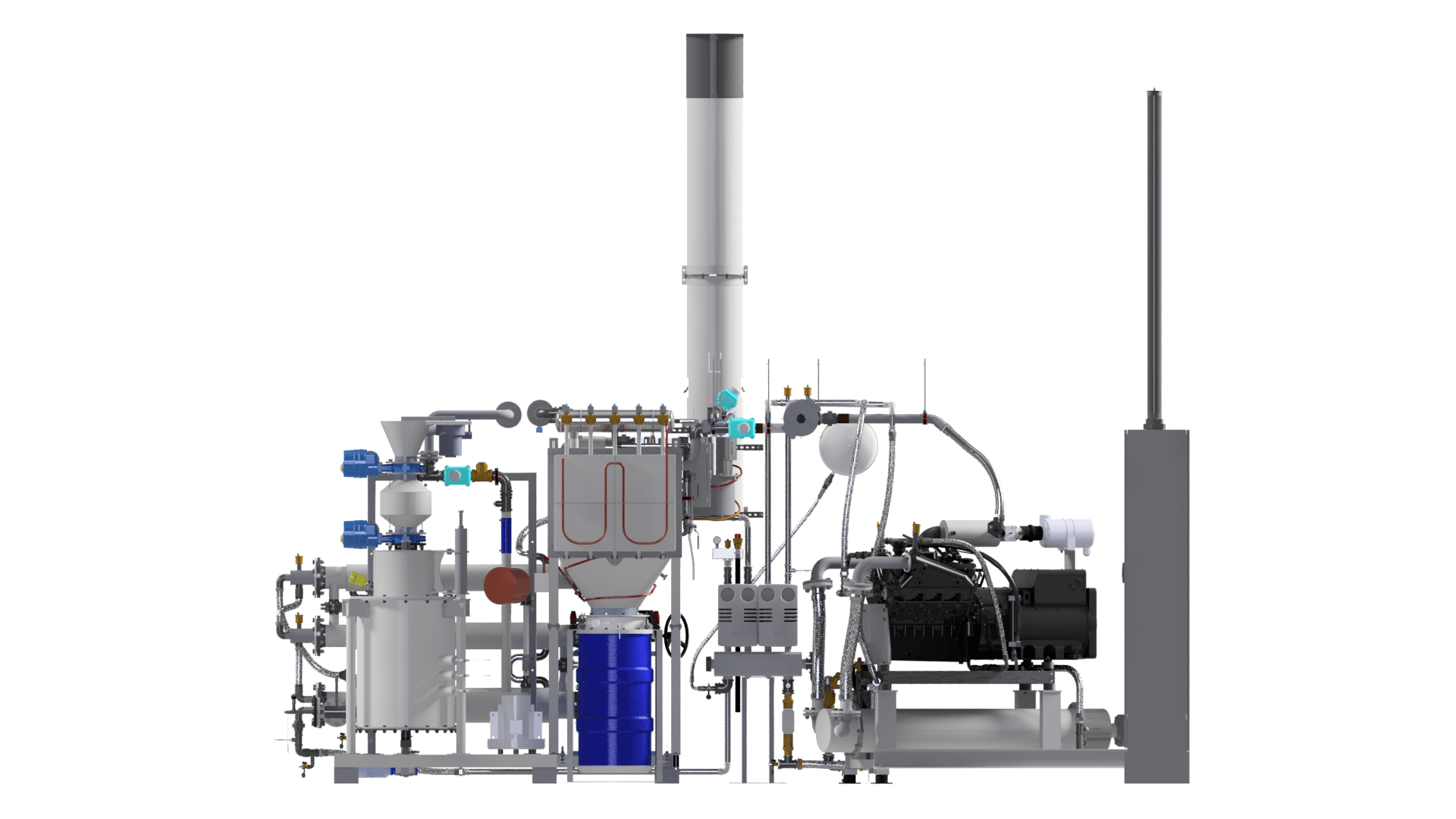

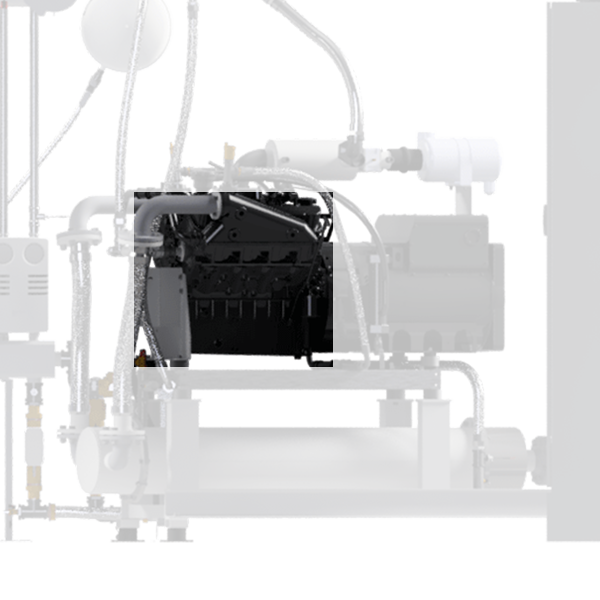

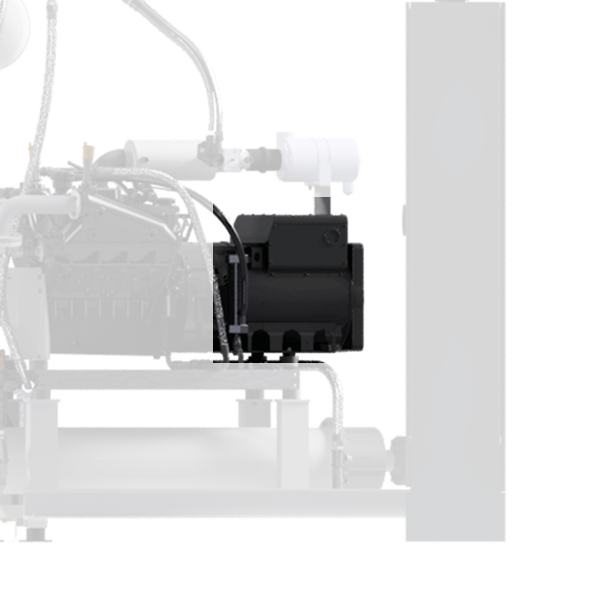

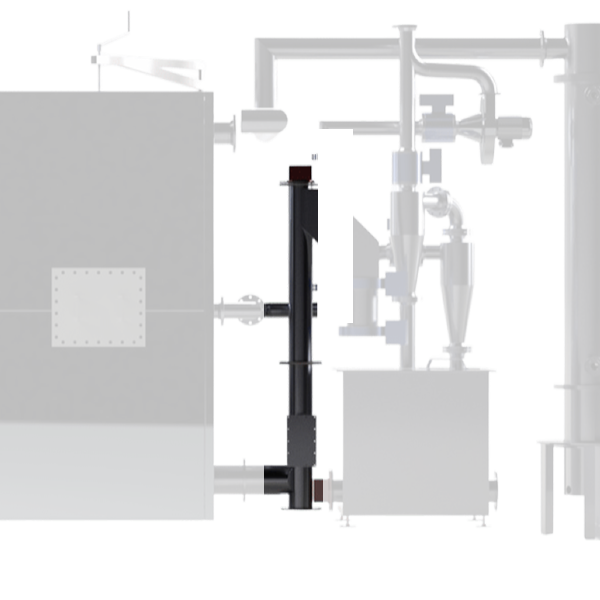

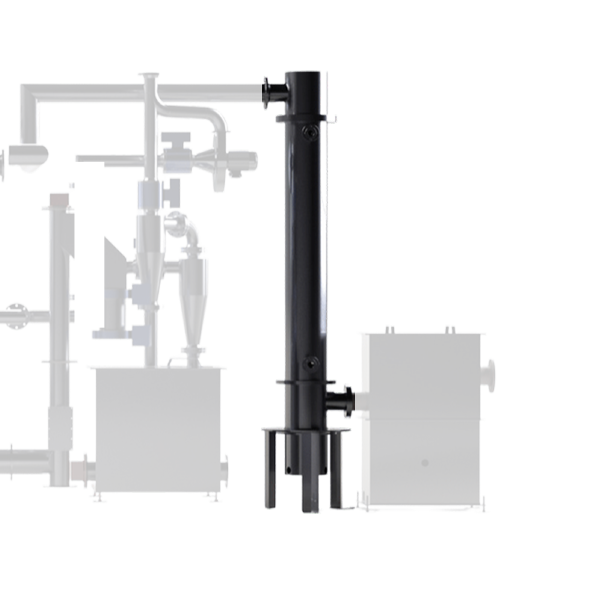

A great deal of heat – known as waste heat – is generated both during the gasification process, in the subsequent gas treatment process, and in the biomass CHP unit. This includes hot exhaust air, hot water from the wood gas and engine cooling, and hot exhaust gases from the CHP unit. While other power plants often let this waste heat go to waste, our biomass CHP units convert it into usable heat thanks to heat exchangers.

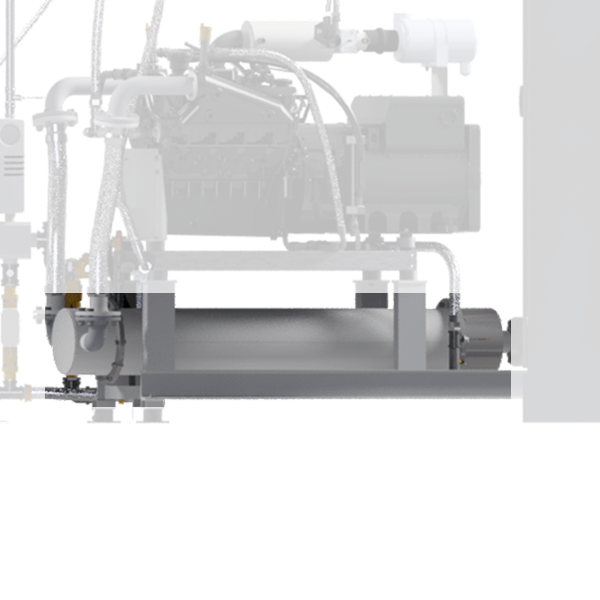

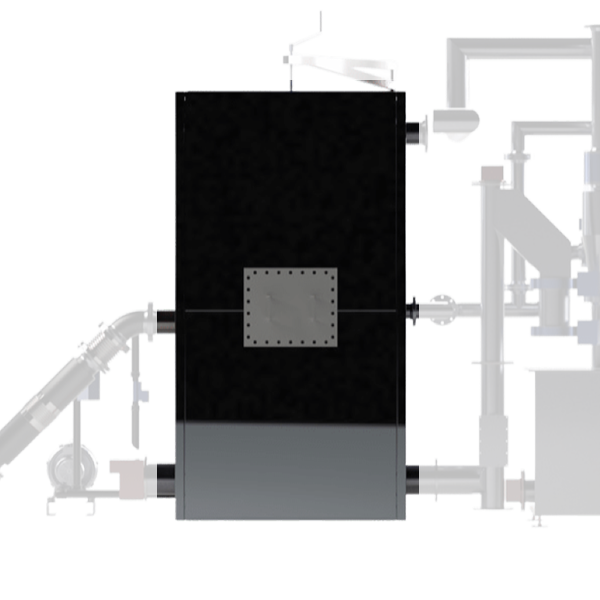

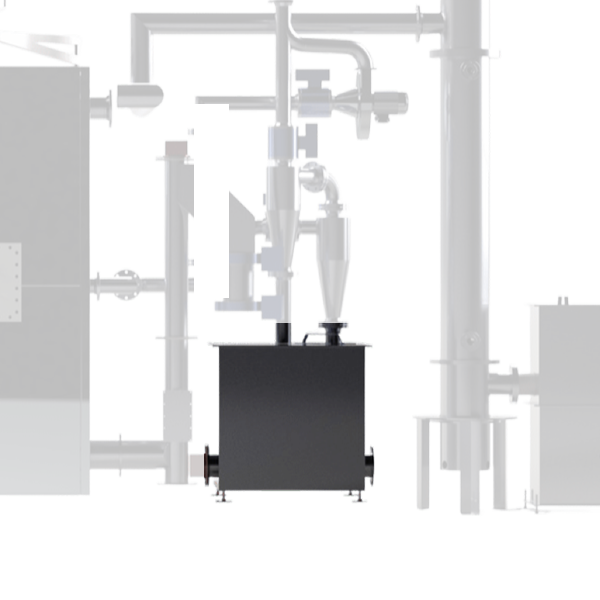

If more heat is produced than necessary or if the heat consumption is not always constant, it can be temporarily stored in a buffer tank and used at another time.

Biomass cogeneration plants therefore have a decisive advantage over conventional power plants: they produce electricity and heat in a process called combined heat and power (CHP). If biomass, such as wood, is now used as a fuel instead of natural gas or crude oil, companies can produce electricity and heat in a climate-friendly, cost-saving way and, above all, around the clock.

If cold is also produced from the heat, one even speaks of CHPC (Combined Heat, Power and Cooling) instead of CHP. Biomass cogeneration plants thus usually convert more than 85 percent of the renewable fuels used into usable energy – it hardly gets any more efficient than that.